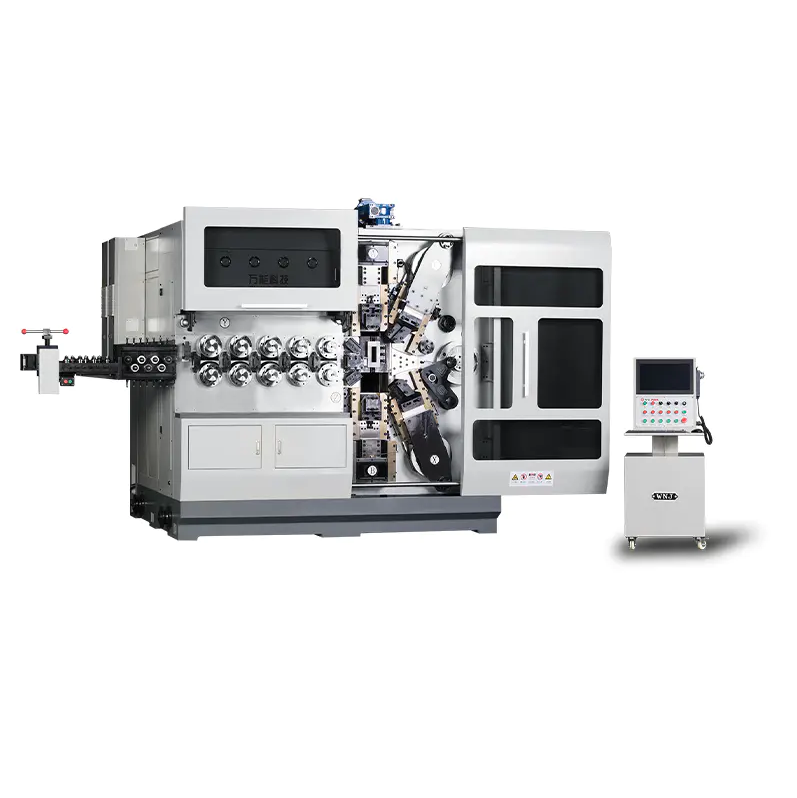

Cold Heading Wire Rod is an essential manufacturing method for the automated production of mass-produced automotive fasteners, motorcycles, bicycles, and home appliances. The shape of the product is continuous, and the grains are not broken, so the strength of the product is improved, especially the mechanical properties are excellent, and raw materials are saved. With the increasing voice of environmental protection, the fastener industry is paying more and more attention to environmental issues. Therefore, the

Cold Heading Wire Rod, which is formed without cutting, is increasingly pursuing high strength and high added value.

1. For the punching with the distance between the shape of the restraint stamping and the edge of the inner hole less than the thickness of the plate, the inner diameter is greater than half of the outer diameter, and the height is more than 1.5 times the inner diameter, the punching effect is better with restraint punching. Due to the close distance between the shape and the edge of the inner hole, the force of the punching needle will affect the shape and change the size of the shape. In order to prevent the external dimensions from changing, this part of the external shape must be in a restrained state. Due to the action of the restraining force, the stamping part is in a state of compressive stress. Under this state of stamping compressive stress, the stamping effect of all bright bands can be obtained by taking an appropriate gap.

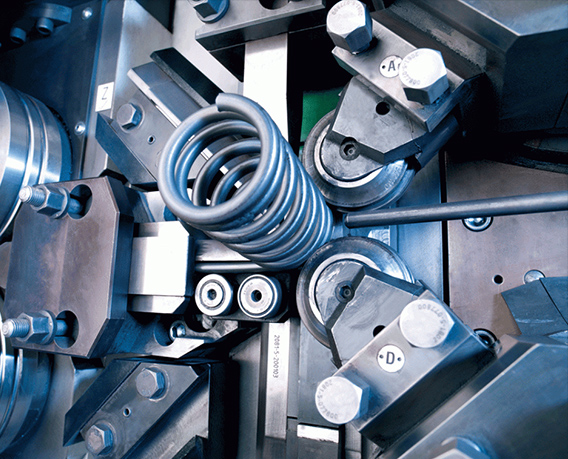

2. Cutting and extrusion forming Usually, the forming of the

Hex Bolt head adopts cold heading plastic processing, and the cutting and extrusion forming process has more advantages than the expansion process. Before cutting and extrusion, the blank must be shaped, and the blank that meets the process requirements can be obtained by shaping. The size of the blank must be paid attention to. The shape of the blank before extrusion should be determined according to the condition of the part, and the shape of the blank that is conducive to the flow of the material should be adopted. If the blank size is too large, that is, the cutting and extrusion allowance is too large, the required cutting and extrusion force is large, which is likely to reduce the life of the cutting and extrusion die, increase the possibility of accidental damage to the die, and consume raw materials; the cutting and extrusion allowance is too small , After cutting and extrusion, the parts are easy to fall off, the shape is incomplete, and the appearance quality cannot be satisfied. The die structure focuses on the design and processing of the cutting and extruding film. The working size of the cutting edge should be controlled at the middle and lower limits as much as possible. The angle of the cutting and extrusion die should be appropriate. The cutting edge must be ground and polished, with a roughness of Ra0.025 to Ra0.050μm. Has a high lifespan.

3. Deep drawing and forging forming are combined with cold-extruded convex thick-walled parts and deep-drawn cup-shaped special-shaped parts into one, using plate as material, and formed by the composite forming method of deep drawing and compression. The forming feature of the fastener is the forming of the head protrusion and the increase of the wall thickness.

4. There are two concepts for partial forming upsetting, one is the overall upsetting, that is, there is a force on the end face of the entire product; the other is local upsetting, that is, only the necessary part has an acting pressure. For overall forming, due to the large processing area and high forming load, a large-tonnage punch is required. For local forming, a lower load can be used to obtain the necessary plate thickness change, which is widely used in the forming of holes and grooves. ① Step parts take the joint as an example to illustrate the main points and applications of forming, engineering design: turning according to the design drawing - annealing - phosphorus saponification - extrusion (semi-hermetic extrusion to form steps). ② Micro local forming for locking and chip removal

English

English 中文简体

中文简体 Español

Español русский

русский

Stock Code: 000906

Stock Code: 000906